3111 Old Lincoln Highway, Trevose, PA 19053 • +1.215.357.5500 • +1.215.357.6216 (Fax) • www.GMPtools.com

|

|

Release No.: GM6090

|

|

GMP Contact:

Ted Clemens, Director of Sales

215-357-5500

info@GMPtools.com

|

|

PR Agency Contact:

Russell-Risko Agency

(215) 343.6565

info@russellrisko.com

|

|

|

FOR IMMEDIATE RELEASE: GMP Celebrates 75 Years.

GMP Celebrates 75 Years of Manufacturing and Engineering Excellence as a Global Provider of Tools and Equipment for the Telecommunications, Power Utility and Cable Television Industries.

August 2011; Trevose, PA -- General Machine Products Company, Inc. (GMP), Trevose, PA, celebrates 75 years of manufacturing and engineering excellence as a global provider of a wide range of products for the telecommunications, power utility and cable television industries, and the contractors who serve them. Founded by engineer George M. Pfundt (1896-1987) in 1936, GMP's product applications include the placement of fiber

optic, copper conductor, and coaxial cable both aerially and underground. GMP aerial cable

lashing machines, Adams® continuous duty winches and fiber optic cable pullers are accepted as the industry standard today. The complete line of GMP's 1,100+ products also includes cable reels and aerial blocks, cable cutters, unique RJ plug pressing tools, fiber optic cable blowing equipment, and other speciallydesigned tools for the data, telecommunications, and power utility markets.

optic, copper conductor, and coaxial cable both aerially and underground. GMP aerial cable

lashing machines, Adams® continuous duty winches and fiber optic cable pullers are accepted as the industry standard today. The complete line of GMP's 1,100+ products also includes cable reels and aerial blocks, cable cutters, unique RJ plug pressing tools, fiber optic cable blowing equipment, and other speciallydesigned tools for the data, telecommunications, and power utility markets.

Today, GMP facilities include a 100,000-square-foot manufacturing plant in Trevose, PA, in

suburban Philadelphia, and in Rutland, England (its CBS Products, Ltd. unit). Both facilities are equipped with a full complement of technologically advanced machine tools manned by a welltrained team of craftspeople.

Looking Back on 75 Years - A Historical Perspective

GMP started operations in Philadelphia as a specialty machine shop serving the local Bell Telephone company and the area's electric utility company. GMP expanded to a production shop manufacturing experimental prototypes after forming close relationships with the Western Electric Company and Bell Telephone Laboratories.

In 1949, GMP and Bell Telephone Laboratories joined forces to pioneer the first modern automatic lashing machine, the Model B Lasher, establishing the telephone industry's standard in lashing technology. Cable lashing machines, sometimes called "lashers" or "spinners", are designed to wind stainless steel wire around telephone, power, and multi-media cable, thereby securing or "lashing" the cable to the supporting messenger strand between poles. Since its introduction, the company has produced over 30,000 lashing machines, some manufactured in the 1950's are still on the job today.

Dedicated to Quality: Today and Tomorrow

For three generations, GMP continues to develop and refine its product lines and continues its investments in new product R&D, state-of-the-art manufacturing, quality assurance, distribution & inventory-control, and physical plant to maintain its leadership position and ability to anticipate and meet the changing needs of work crews in the telecommunications, power utility and cable television fields.

"We are proud to have reached this tremendous milestone," said William N. Pfundt, President and C.E.O. of GMP, and the third generation to lead the company. "But, we won't stop there. We're dedicating the next 75 years to improvement on a tradition of reliable support and quality engineered products," he added.

For example, GMP has recently doubled its investment in its flexible manufacturing system (FMS) capability. Consisting of automated CNC machines that are connected by a material handling system to optimize parts flow, FMS provides for flexibility that allows the system to react in the case of anticipated or unanticipated changes. This high flexibility in managing manufacturing resources, like time and effort, allows GMP to produce its products faster, with lower-unit costs, with improved quality, with greater labor productivity, increased system reliability, greater machine efficiency, reduced parts inventories, and shortened lead times. This is just one example of how GMP is committed to maintaining and improving its manufacturing base in the USA.

To reduce its carbon footprint, and to maintain its cost competitiveness, GMP has "gone Green" with the advent of its Solar Energy Initiative. A solar panel array was recently installed on the roof of its Trevose, PA manufacturing facility. Solar photovoltaic panels, also known as photovoltaic cells, are packaged interconnected assemblies of solar cells that generate and supply electricity. The solar array installed at GMP will provide considerable relief to the environment by offsetting 198,416 lbs. (90,000 kgs.) of CO2 per year, an amount roughly equivalent to the CO2 sequestered by a 30-acre forest of mature trees, or the recycling of 5,400,000 aluminum cans per year.

Poised to Meet the Demands of Utilities Worldwide: Now and In the Future

William Pfundt is proud of the accomplishments of his father and grandfather, but believes there is more work to be done. To meet the challenges of global telecom, power and cable television utilities and the contractors who serve them, Mr. Pfundt has led the company forward by spearheading the creation of worldwide sales organizations covering Eastern Europe, the Middle East and Africa, as well as across Latin America and Asia. Because of his leadership, GMP tools can be found on the job in Dublin, Ireland and Dubai, United Arab Emirates; from Delhi, India to Durango, Mexico.

GMP is geared to engineer and supply the tools and equipment required by the world's utilities and contractors, today and into the future. As its quality statement affirms: "GMP supplies defectfree products and service, on time, which meets its customers' expectations." Only time will tell of what new advances GMP will offer in the next 75 years.

Significant Historical Dates

1918 — George M. Pfundt, a young U.S. Army veteran with a degree in Mechanical Engineering from the Franklin Institute in Philadelphia, sets up a modern shop in that city. The Bell Telephone Company of Pennsylvania quickly becomes an important customer.

1936 — George M. Pfundt and his wife, Anna, found General Machine Products Company (GMP), an engineering and machine shop, as a family-owned business in the basement of a building in Philadelphia's "Old City" area. GMP counts among its principal customers the local Bell Telephone Companies, Philadelphia Electric and the Pennsylvania Railroad.

1937 — GMP expands to a production shop, following the award of manufacturing contracts from Western Electric Company, and subsequently forms a close relationship with Bell Laboratories, in Murray Hill, NJ. The association with Bell Labs enables GMP to manufacture prototypes and future products for the Bell System.

1947 — Working with Bell Telephone Laboratories, GMP pioneers the modern automatic lashing machine (or, "cable lasher"), thereby establishing the international industry standard in lashing technology.

1952 — GMP manufactures special prototype equipment for Bell Telephone Labs destined for use in the Distant Early Warning (D.E.W.) Line. GMP later becomes a prime contractor to Western Electric Company during the construction phase from 1954 through 1957.

1956 — G. Nelson Pfundt, George M. Pfundt's son, joins GMP and becomes the second generation of Pfundts to be active in the business.

1957 — Having outgrown the Philadelphia factory, GMP moves to its present headquarters in Trevose, PA, a suburb of Philadelphia. Here, GMP builds a 100,000 square-foot, state of the art engineering and production facility, later expanded to 125,000 square feet.

1963 — GMP acquires Philadelphia Chain Hoists and offers a full line of hoisting equipment for industry. (The firm subsequently divests this product line in 1983.)

1966 — GMP receives a Research Institute of America award in recognition of it's "furthering business research and stimulating the personal and professional growth of its employees."

1966 — In recognition of his 50-plus years of service to the telephone industry, George M. Pfundt is awarded Lifetime Membership in the Independent Telephone Pioneer Association.

1966 — George M. Pfundt becomes chairman of the board and his son, G. Nelson Pfundt, becomes president of GMP.

1970 — GMP installs its first NC machine tools for turning and milling. This investment in modern production technology perpetuates a cornerstone of GMP's successful operating philosophy of "reducing total product cost through continuous productivity improvement."

1973 — GMP acquires Adams Engineering, producer of Bell System standard winches for cable placing, which were developed in the 1950s. GMP continues to add practical design enhancements to the Adams Continuous Duty Winch product line.

1978 — GMP develops fiber optic placing equipment that is deployed in field trials of this new cable technology. Continued product development results in the introduction of a full fiber optic product line by 1980.

1980 — G. Nelson Pfundt is elected to the Board of Directors of the United States Telecommunications Suppliers Association.

1983 — William N. Pfundt, G. Nelson Pfundt's son, is recruited to GMP from Northern Telecom. He is the third generation of Pfundts to join the family business.

1983 — GMP introduces industry's first professional-grade field installation crimping tool for modular plugs. Go to www.GMPtools.com/nf/70630.htm for the complete story.

1986 — Company founder George M. Pfundt dies at the age of 90.

1992 — G. Nelson Pfundt ascends to Chairman of the Board and William Pfundt is elected to president of GMP.

1994 — GMP introduces the Adams® CD Lite Winch. This smaller, lightweight continuous-duty winch suits customer requirements for fiber optic and innerduct placing using downsized fleet vehicles. Go to www.GMPtools.com/nf/70601.htm for the complete story.

1995 — GMP achieves ISO-9001 certification.

1998 — GMP introduces the Apollo Lasher. Its innovative design offers features that respond to the unique placement requirements of lightweight broadband aerial cable construction for the information superhighway. Go to www.GMPtools.com/nf/70400.htm.

2000 — GMP begins sales operations in Latin America.

2003 — The Model C Lasher becomes the Model C2 Lasher. The new lasher offers increased cable or bundle capacity, overlash capability, and a larger drive housing opening to prevent wear on existing cable. Go to www.GMPtools.com/nf/71422.htm.

2003 — GMP begins sales operations in the People's Republic of China. The office, located in Shanghai, supports the company's marketing efforts by offering its specialized cable placement equipment and tools to China's high-growth communications industry and power utility market.

2004 — GMP acquires UK-based manufacturing company CBS Products LLC, adding cable blowing equipment such as the Breeze, the Tornado, and the AccelAir to their large assortment of equipment. Go to www.cbsproducts.com for more information.

2005 — GMP introduces the Breeze Micro Fiber Cable Blowing Machine to meet the growing demand for micro fiber cable installation. Go to www.GMPtools.com/nf/89010.htm.

2005 — GMP introduces Duct Rodders. Their flexible and resilient design make them the perfect tool for underground duct work tasks such as cleaning and locating ducts, threading lines, and pulling cables. Go to www.GMPtools.com/nf/89202.htm for the complete story.

2008 — GMP introduces a line of Fiber Optic Reel Handling equipment that ensures the safe and efficient placement of delicate fiber optic cable. Go to www.GMPtools.com/EB/GM6135EB.html for the complete story.

2010 — GMP introduces the AirStream Cable Blowing Machine. This machine complements GMP's line of cable blowing equipment and handles the smallest FTTX jobs. Go to www.GMPtools.com/nf/89300.htm for the complete story.

2011 — GMP introduces the Ramrod Trailer-Mounted Powered Duct Rod Pusher for placing pulling lines or fiber optic cables into new, old or crowded conduits. Go to www.GMPtools.com/nf/88900.htm for the complete story.

More information is available online at: GMPtools.com or by contacting Ted Clemens at 215-357-5500; info@GMPtools.com.

* * *

Editor's Note:

A high-resolution photograph [6 MB TIF] is available to accompany this release. Go to www.GMPtools.com/images/GmpHistoricalPerspective.tif (Click on or paste this link into your browser's address field).

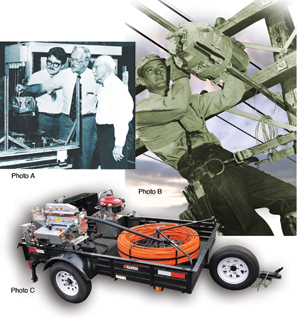

Photo A Caption:

Three generations of continuous leadership at General Machine Products Company -- William, Nelson and George Pfundt.

Photo B Caption:

In 1949, GMP joined forces with Bell Telephone Laboratories to pioneer the first modern automatic lashing machine, the Model B Lasher, establishing the telephone industry’s standard in lashing technology.

Photo C Caption:

The recently introduced GMP Ramrod Trailer-Mounted Powered Duct Rod Pusher.

# # # # #

Download this document as a PDF file.

|

|

|